Associate

Looks great, I am going to have to build one of these eventually!Finally got my Voron 2.4 to the point I can print. Still a fair bit of work to do but at least it prints.

Looks great, I am going to have to build one of these eventually!Finally got my Voron 2.4 to the point I can print. Still a fair bit of work to do but at least it prints.

@Demon got a decent link to the Raise printer?

If I'm doing production work, vorons will be a lot of work to just build. Is that what you want, or you just want to get going with it?

why/how corexy an ender 3?What does your work use the machines for, prototyping?

My personal setup right now is:

FLSUN V400: final quality part, and prototyping. Always in PETG.

FLSUN QQ-S Pro: Dedicated to rubberised parts (e.g. TPU) as not currently accurate or reliable enough for normal parts (massive custom modd coming up though).

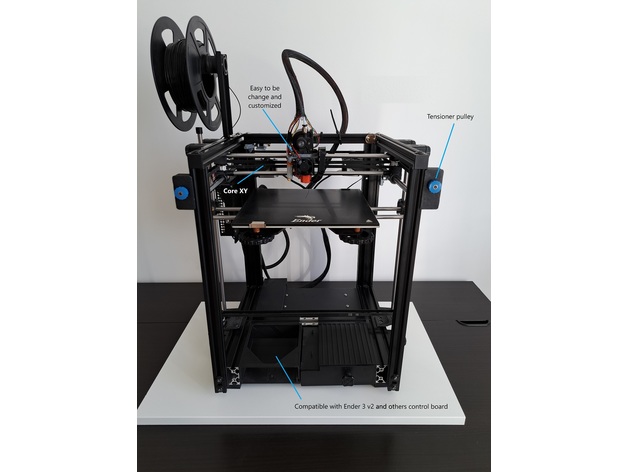

Ender 3 V2: Dedicated for Carbon Fibre PETG with 0.6 nozzle for strong parts when needed. This is already a massively modded printer, but it should soon be getting converted to CoreXY, as I'm not happy with the height mod I did a while back.

I should ideally buy another printer for dedicated prototyping with PLA.

Definitely in favor of spending more to get quality these days.

I've already dual Z belted the Ender 3V2, linear rails, direct drive, externalized PSU and board etc. I recently increased the height by 150mm using longer extrusions (relatively easy since belted), but I've not been happy with how that worked out with some binding of the setup. I also get pretty bad ringing. (Present before the height increase)why/how corexy an ender 3?

looking it up, it appears that it's basically just making it into an ender 5 with corexy?

Seems odd it doesn't have a crossbar at the top front. Convenient for getting to the bed but would have thought it'd make it less rigid.

A few things that spring to mind:

A few things that spring to mind: